Lada Niva

40 years of popularity.

LADA NIVA 4 x 4

Below is a list of this dashing car technical development progress.

Engine and systems

Engine values remain unchanged.

Versions Euro III and Euro IV differ by the exhaust manifold and precious metal content inside the neutralizer.

Operation manual allows the application of fuel with OR-92, still some decrease of power factors can be seen.

New gaskets with elastic silicone roller that maintain their sealing characteristics within the whole life cycle of the car and do not require any retorque are used in order to exclude cooling fluid leakiness.

New imported filler block preventing the leakiness of the water pump is installed in order to enhance the operating life of the water pump bearing. Fuel supply system has been deeply modified; it foresees fuel filter transfer from the engine compartment to the bottom part of the car and implementation of quick disconnect couplings.

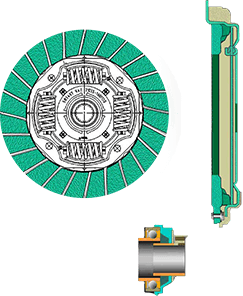

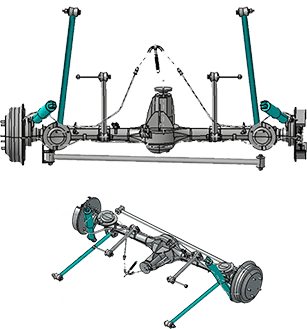

Transmission

Coupling engagement of 200 mm is changed by the new enforced one of 215 mm made by the Valeo Company, which analogous to the coupling used for Chevrolet-Niva cars. Approved resource enhancement is equal to 120 thousand km. Performance reliability in complicated road conditions has been improved. Modified damping unit eliminates starting and gear change vibration, moreover, jointly with the new drive gear it decreases the pedal effort for 40 %, the necessity to adjust clutch linkage has been eliminated, and the “clutch bearing noise” defect has been removed.

Transfer gear is assembled applying silicone sealant, which has replaced fiberboard gaskets. Improved crankcase ventilation system RK with an open bleeder eliminates the pressurization inside the crankcase RK.

Cardan shafts are made by “Cardan” factory in Syzran, where the new equipment have been used; manufacturing of the above cardan shafts complies with the higher requirements for the overbalance and geometrical relationship, i.e. noises and vibration are reduced, the operability and cardan shaft life are significantly increased.

Improvements

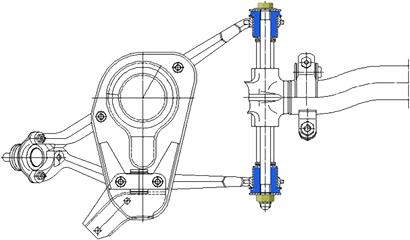

Silentblocks

Vulcanized silent-blocks of increased dimensions made by ANVIS-Rus Company will:

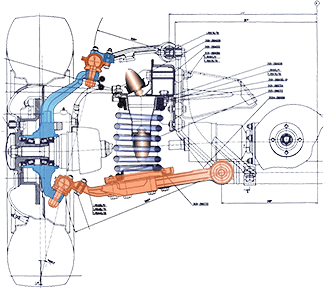

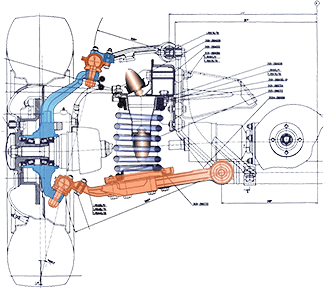

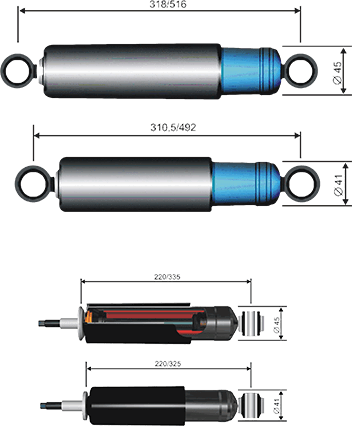

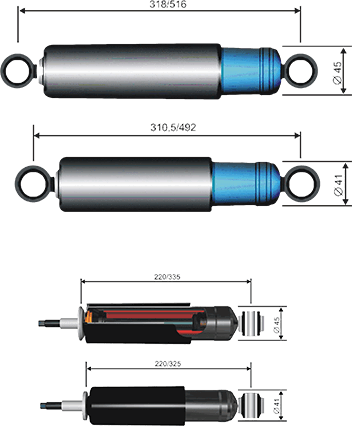

Shock absorbers

VAZ 21214 M

General improvement of wear characteristics:

Angle-wise installation of bottom links to the axis of bank reduces the cross traverse movement and angular motions of the rear axle:

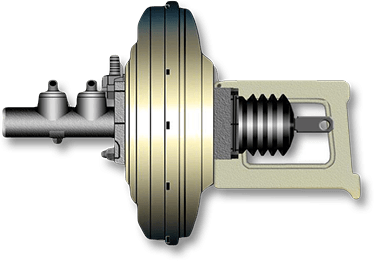

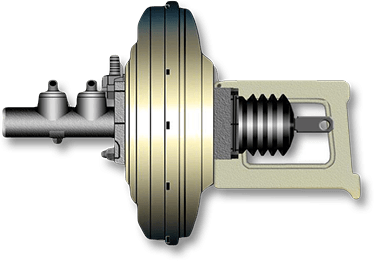

Brakes system

9 inch vacuum booster is installed instead of the 8 inch; the new aluminum brake master cylinder of 22,22 mm is installed instead of the cylinder with 20,64 mm diameter.

Better wear characteristics

Headlights

Dashboard

Installation of a complex instrument board VAZ-2115 with new facing:

Mirrors in plastic housing with increased visibility, prevention of blinding with headlamps:

Rear suspension

Modification history:

Angle-wise installation of bottom links to the axis of bank reduces the cross traverse movement and angular motions of the rear axle:

And that's not all.

All modifications are not the last step in the planned life cycle of LADA 4×4 cars.

Double bearings of a transfer gear output spindles enables the sufficient decrease in endfloats and outruns, the new gaskets of a transfer gear and front and rear axle reducers with additional protective edge.

Dynamic vibration absorbers reduce vibration transfer from power-transmission plant to the car body.

And finally, the new interior, made by injection casting of a polypropylene instead of ABS-formed, separately foldable rear seats (both beds and backs), new convenient and safe clicks.

Rear seat structure will enable the fitting of 2 children-seats and will comply with the requirements of “Isofix” standard.